ONOSI Solar

News

Intelligent Temperature Control Principle vs Thermal Barrier Valve Principle

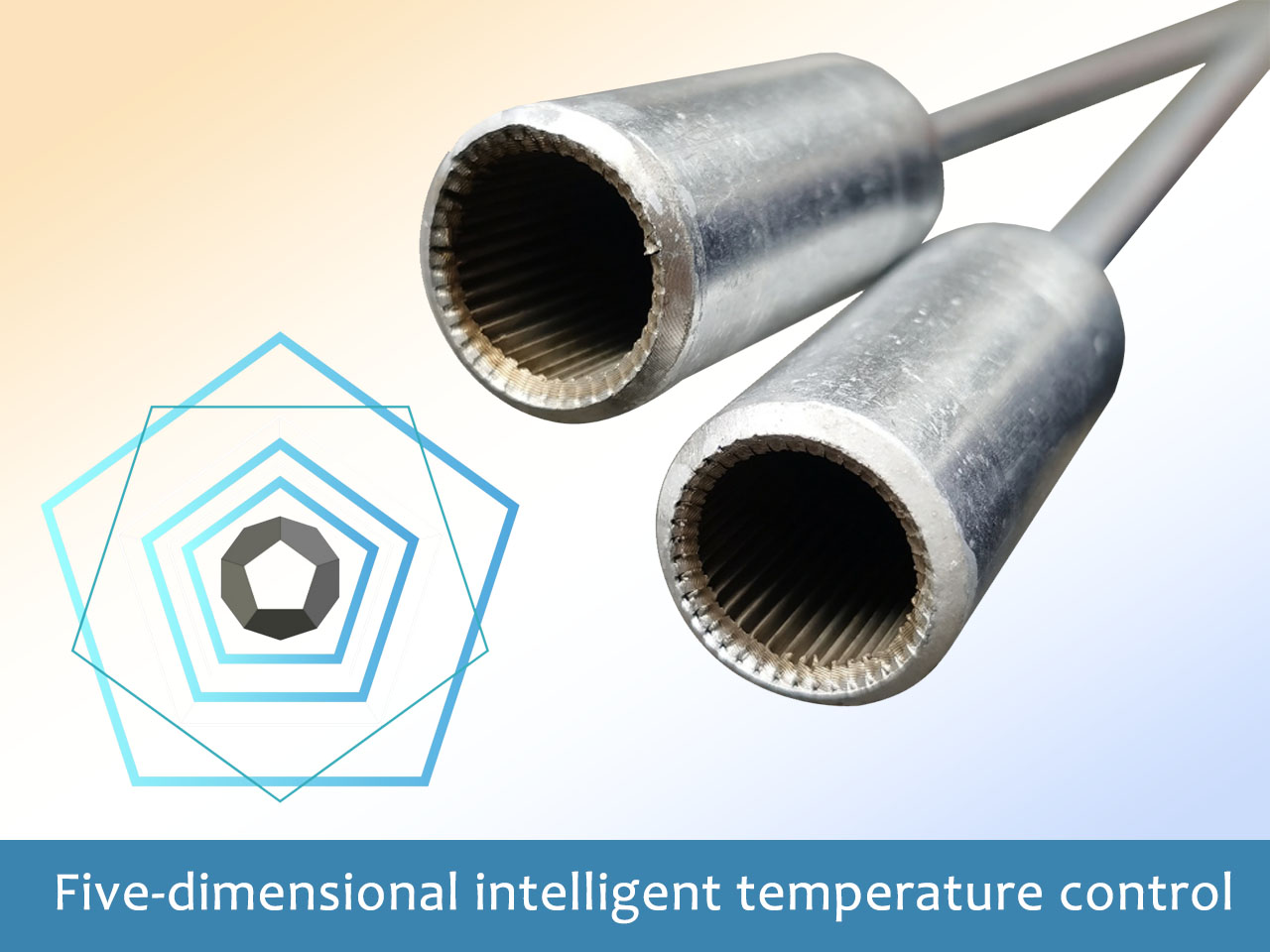

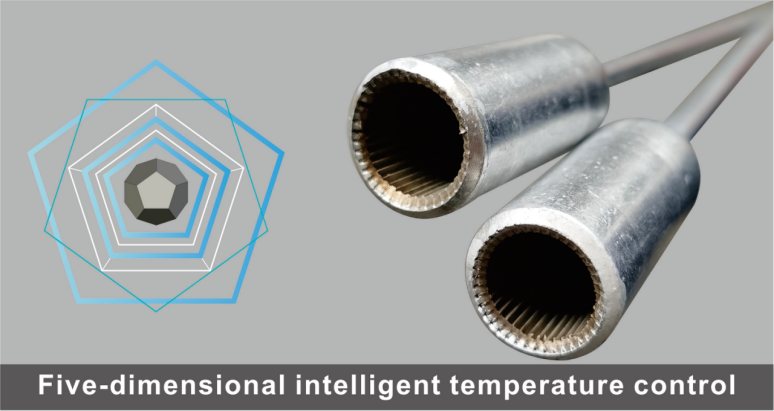

Intelligent Temperature Control heat pipe:

ONOSI intelligent temperature control heat pipe accurately controls the temperature inside the collector and water tank, solving overheating problems in the most effective way:

1. Working mechanism: Immediately stop or gradually stop heat transfer (within 5 ℃) at the set working temperature point.

2.Working principle: Intelligent sensing of temperature changes, adaptive stopping of phase transition at high temperatures

3、Operating characteristics:

3.1Stop heat transfer immediately upon reaching the set temperature point, and resume heat transfer immediately below the set temperature point, with absolute consistency

3.2Stop heat transfer when there is excess heat, but immediately restore performance when there is no excess, fully meeting the ideal temperature control requirements

3.3The function of blocking at high temperatures does not affect the heat transfer performance under normal working conditions

4、Other applications: Temperature controlled solar collectors, preventing high-temperature carbonization of antifreeze, solving problems such as secondary installation of solar energy, loss of heat transfer capacity caused by carbonization of antifreeze, and regular replacement of antifreeze for 3 years.

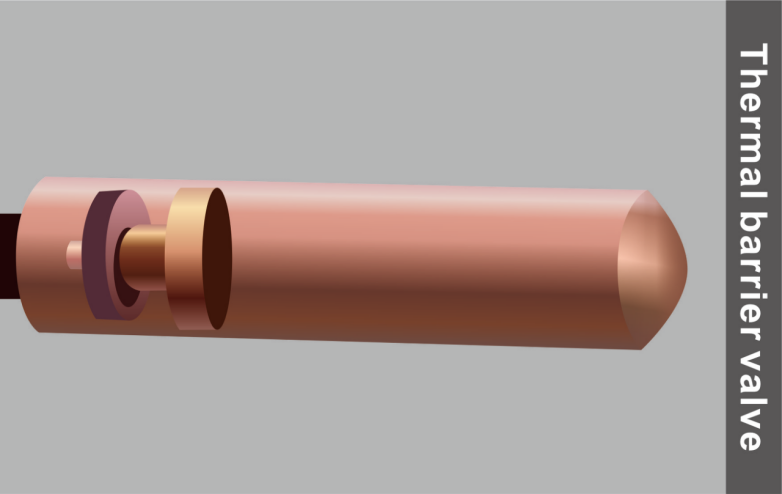

Thermal barrier valve heat pipe:

1、Structure: Dual spring drive mechanism composed of memory alloy spring and ordinary spring+plug cap

2、Working mechanism: At high temperatures, the output force of the memory alloy spring is greater than that of a ordinary spring, which pushes the plug cap to seal the condenser head; At low temperatures, the output force of the memory alloy spring is lower than that of a ordinary spring, which pushes the plug cap away from the end of the condenser head

3、Working principle: Shape memory alloys undergo martensitic austenite phase transformation when the temperature changes, and their mechanical properties vary in different states

4、operating problems

4.1The phase transition process is very slow, with a phase transition interval of several tens of degrees, and the heating and cooling intervals are different, so precise temperature control cannot be achieved

4.2The memory alloy spring cannot sense the temperature of the heated water and can only be thermally coupled with the evaporation end of the heat pipe (i.e. installed at the evaporation end). In this working mode, the system cannot be restarted on the same day after overheating is turned off, which cannot meet the actual requirement of only short-term overheating protection, but immediately turning on when it is not overheat

4.3The dual spring drive mechanism has a short stroke, and in order to achieve high-temperature sealing, the plug is closer to the end of the condenser at low temperatures, resulting in a loss of heat transfer capacity under normal conditions.