ONOSI Solar

Solar Collector

Heat pipe solar collector

- Brand: ONOSI or OEM

- Payment: T/T or L/C

- Delivery time: 15 days

- Minimum order: 1 set

- Shipping port: Shanghai or Ningbo

1) Perfect Anti-dry performance and 280 degrees of long-term dry conditions do not burst tube;

2) The copper pipe in the heat pipe could transfer the energy into the cold water in the pressurized manifold rapidly;

3) If some of heat pipes are broken, the whole system could still work very well;

4) Non-bursted tubes, non failure, not down efficiency after long-term use;

5) Moretransmission power, and small thermal resistance, the heating water temperature is more higher;

6) Better performance of Antifreeze resistance and air drying;

7) No water inside the tubes, heating conduction by Copper heat pipe;

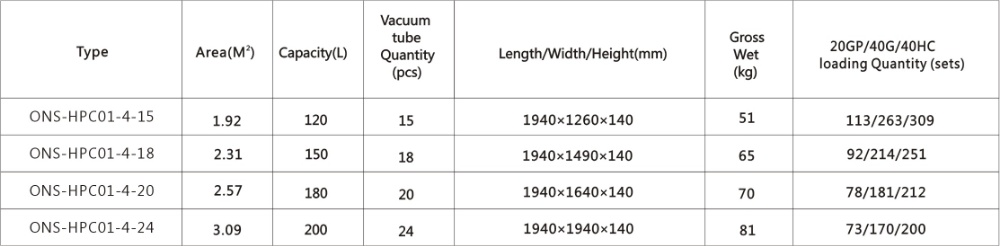

Heat pipe solar collector Parameter table:

- What is heat pipe solar collector?

- Advantages of heat pipe solar collectors.

- The composition of the heat pipe solar collectors

- How does a solar thermal collector work?

What is heat pipe solar collector?

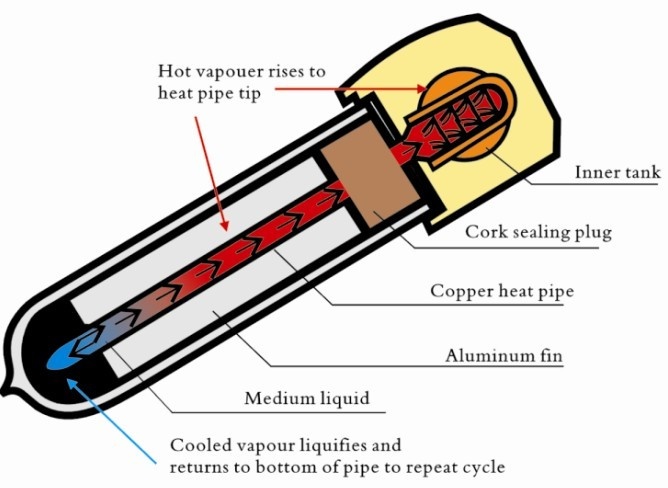

The heat pipe solar collector (Vacuum tube solar collector, Evacuated tube solar collector) always connected with existing water heating device. The selective absorber coating on the inner cover of vacuum tubes absorb solar energy, then convert solar energy into thermal energy and transfer thermal energy to heat pipe by aluminum fin. The heated liquid inside heat pipe change into vapor which rises to the top condenser, then thermal energy heat transfer liquid pass through heat exchanger and the cooled vapor becomes liquid, returning to the base of heat pipe.

The thermal energy conducts to transfer liquid via a copper pipe. This transference of heat into the liquid creates a continuous circulation as long as the collector is heated by the sun.

Advantages of heat pipe solar collectors

Heat pipe solar collectors are a new type of solar collectors which can absorb and transfer solar energy more efficiently. These type of collectors have the advantages of both heat pipes and evacuated tube collectors. Additionally, controlling operating temperature, overheating prevention, long operating lifetime, and also corrosion elimination are other advantages of heat pipe solar collectors. These unique advantages have turned heat pipe solar collectors into an attractive option for solar domestic water heating systems.

The composition of the heat pipe solar collectors

The solar thermal collector system mainly consists of heat pipe solar collector; water storage tank; central control unit; thermocouples; pump; flow meter; pipes and fittings; and valves.

How does a solar thermal collector work?

A portion of the solar radiation which strikes the glass of heat pipe solar collector is absorbed and used to vaporize the working fluid inside the heat pipes and the remainder is dissipated back into the environment. The vapor inside the heat pipes rises towards the condenser section where transfers its heat to the solar working fluid through the manifold, condenses, and returns to the evaporator section, and the cycle continues. The solar working fluid, which is circulated using a pump, enters the manifold at low temperature and its temperature rises as it passes along the manifold. The heated solar working fluid then passes through the copper coil to exchange its heat with the water inside the tank. Heated water is extracted from the top of the storage tank at 60 °C based on the hot water onsumption pattern and replaced with tap water from the bottom of the storage tank.

A pump was used to circulate the solar working fluid in the solar loop. The flow rate of the solar working fluid was regulated via a valve installed after the pump. The low temperature solar working fluid (2 l/min) entered the manifold and its temperature was raised as it passed over the heat pipe condensers. The heated solar working fluid then passed through a 34 m copper coil (with external heat transfer area of 1.45 m2) which was installed inside a 210-liter storage tank to exchange its heat with the water inside the tank. The storage tank was insulated with a 50-mm layer of thermal insulation materials.