ONOSI Solar

News

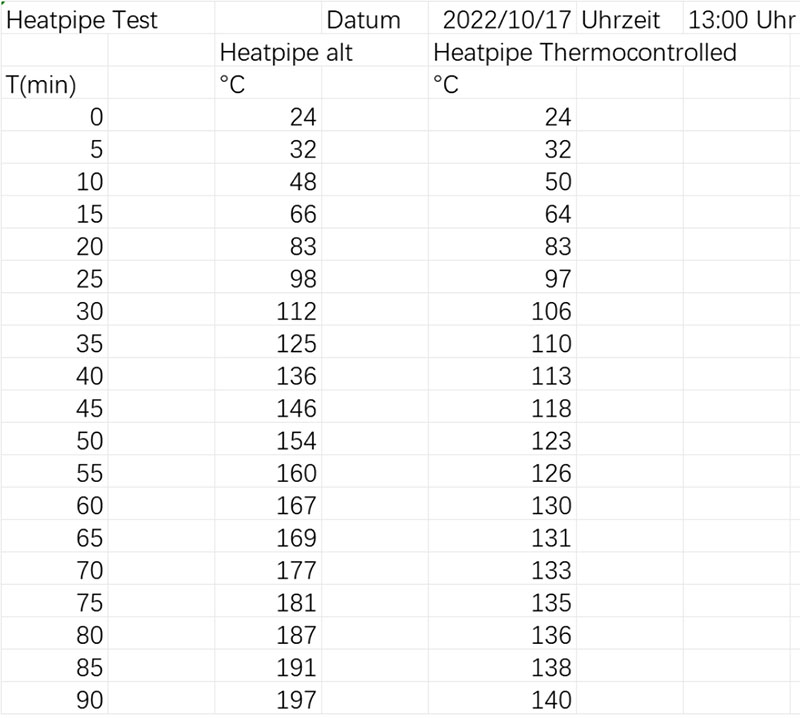

Comparison of temperature testing between temperature control heat pipe and conventional heat pipe

This is the result of a 90 minutes stagnation test conducted on a temperature control heat pipe and a conventional heat pipe under the same gasification conditions. It can be clearly seen from the record sheet that:

1.From the 0th minute to the 25th minute (temperature within 100 ℃), the heating rate of both sides is basically the same.

2.At the 30th minute, the temperature control heat pipe has reached the critical point of the set temperature, and the heating rate has slowed down, while the conventional heat pipe heats up rapidly.

3At the 35th minute, the temperature control heat pipe has reached the temperature control set point (110 ℃), while the conventional heat pipe continues to rapidly heat up.

4.From the 35th minute to the 90th minute, the temperature of the temperature control heat pipe increased to 140 ℃, while the temperature of the conventional heat pipe increased to 197 ℃.

Question: Why does the temperature still slowly rise after the temperature control heat pipe reaches the set point and the heat transfer stops?

This is due to the inherent thermal conductivity of metals. At this time, the temperature inside the vacuum tube has exceeded 200 ℃ and is still absorbing heat, so the temperature of the metal body of the heat pipe is slowly rising. But this increase is only due to the temperature of the pipe body, there is no heat transfer anymore.

At this time, heat is released from both heat pipes, and the temperature control heat pipe will quickly drop to around 110 ℃, while the conventional heat pipe will slowly drop to around 185 ℃. This is because the temperature control heat pipe has stopped heat transfer, while the conventional heat pipe continues heat transfer.